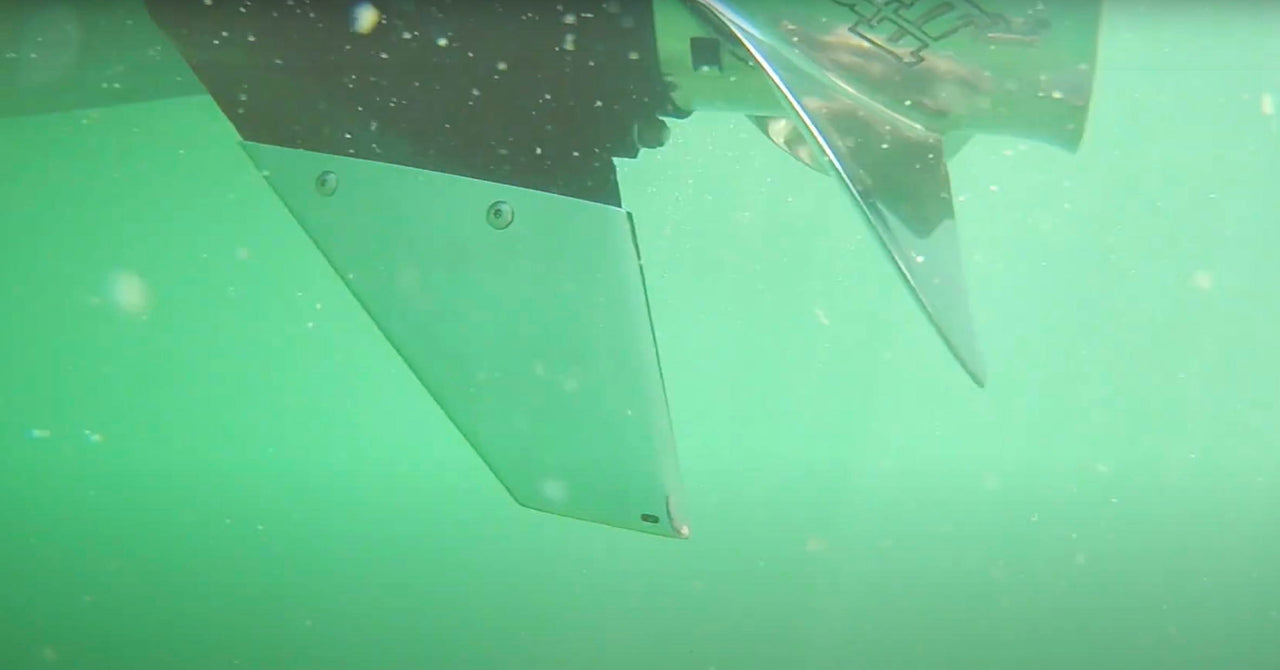

Ineffective steering, lack of directional stability, running rough and excessive vibration from your motor when opening the throttle — each of these is a sign that it’s time to look at your skeg. Of course, you may have noticed it looking beat up while trailering your boat or removing your prop, too. The bottom line is that if you have warping, chips, or even chunks taken out of your skeg, do not ignore it! It may be time for skeg repair or skeg replacement.

Thankfully, this may be one of the easier and less costly repairs you can do to seriously help your motor, and when you get it fixed, it can save you more than you might realize.